Champion is an institution. The American heritage brand established by the Feinloom brothers in 1919 in Rochester, New York, was here with an eye on quality athletic garments long before sportswear was ever considered fashionable.

Throughout the ’60s to most of the ’90s, brands like Nike, adidas, and Reebok, weren’t seen at all on the courts and fields—rather, Champion was the sole brand outfitting the NCAA, later supplying the NFL in the ’70s and the NBA in the ’90s.

photo: champion-eu.com

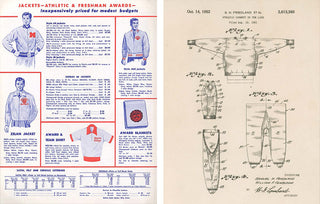

But even before all that, Champion was a heralded and trusted brand because of a simple technique in modern apparel production that proved to be a technological marvel—their invention of the Reverse Weave.

Champion’s crowning achievement was found in their most basic items. We sometimes joke here about how you often spot dads rocking that Champion crew-neck as they mow the lawn, get dragged back and forth at amusement parks, and barbecue with the neighbors. You know, dad-ly things. It’s usually heather grey and a bit dingy, but what we fail to realize is that that same sweatshirt was actually purchased eons ago when dad was a raging alcoholic at UCLA. This is because Champion’s sweatshirts and T-shirts constructed with this process were nearly indestructible and made with the grain of the fabric running sideways.

photo: championstore.com

Most shirts, especially inexpensive T-shirts, stitch vertically because it’s faster and more cost-effective to stitch in one straight line. However, after listening to the concerns of the coaches about shrinkage when washing big batches of athletic wear, Champion decided in 1934 to go against the grain, literally, and stitch their athletic gear with a more time-consuming but superior transverse method which was cut on the cross-grain. While the sleeves may fray and the yellow pit stains remain, there was nothing that would affect the structure and construction of the T-shirt or sweatshirt after the updated method; a testament to Champion’s pioneering of Reverse Weave—shrink resistant, durable, and made to last.

photo: championstore.com

Initially patented in 1938 and finalized years later in 1952, decades later, Reverse Weave was so sought after in Japan that thrift stores would import tons of clothes from the United States and allow enthusiasts to sort through the bales of clothing to find the garments. To celebrate their 60th anniversary, the brand officially relaunched a Reverse Weave collection in Europe in 2012, following coveted collaborations with colette in 2008 (designed by a younger Virgil Abloh), and brands like nanamica, Supreme, XLARGE, Stussy, and A Bathing Ape. Many of the same techniques exhibited by Champion can be found produced by fleece manufacturers like Canada’s CYC, the parent company behind Reigning Champ, wings + horns, and maker of most Supreme’s hoodies. Brands like Neighborhood and WTAPS are also known to use Reverse Weave as well.

Quality in clothing has to start somewhere. For denim, it was with the sturdy metal rivets found in Levi’s, and for sportswear, it was Champion’s enduring Reverse Weave.

***